Heap leaching - Wikipedia

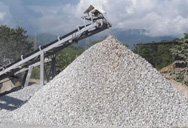

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of stone reactions that absorb specific minerals and re-separate them after their division from other earth materials.

Heap leaching | industrial process | Britannica

Other articles where Heap leaching is discussed: gold processing: Cyanidation: …extracting gold from low-grade ores, heap leaching is practiced. The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the gold.

A Brief Note on the Heap Leaching Technologies …

Heap leaching is a low-cost technology used in industrial mining to recover precious metals such as gold and uranium, along with several other highly sought after metals like copper, from their primary resources (ores and minerals). For many decades, there has been a growing demand for heap leaching due to its environmental benefits. Heap leaching provides mining operators with a benign ...

(PDF) Heap Leaching Technology-Current State, …

Heap leaching is a well-established extractive metallurgical technology enabling the economical processing of various kinds of low-grade ores, which could not otherwise be exploited.

Optimization of the Heap Leaching Process …

Modern approaches to mine production require simulation frameworks that can increase mineral recovery and are robust in mitigating feed variations [].This work presents a methodology for the evaluation of heap leaching, incorporating information of the mineralogical composition of the inputs; the approach is based on discrete event simulation (DES).

Heap Leaching, Heap Leaching Consulting, Heap …

Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from low-grade gold ores. In this process, ore is firstly crushed to fine particles. By spraying leaching solution to the large piles, the gold-containing solution is leached.

HEAP LEACHING GUIDE - Senninger Irrigation

Heap leach depths have increased to more than 500 ft of ore depth from only 50 to 65 ft a decade ago. MINI-WOBBLER®LATERAL LINE EMITTER NOZZLE ORIFICE SIZES #8 1/8" (3.17 mm) #6 3/32" (2.38 mm) #7 7/64" (2.78 mm) Layers of coarse and fine textured material during material comprise leach piles. Leaching solutions flow more readily in

HEAP LEACHING TECHNIQUE in MINING - Euromines

Heap leaching is a tried and tested mining technique enabling the processing of different kinds of ores which could not otherwise be exploited under viable economic conditions. Modern day heap leaching, which has a relatively low level of energy consumption, is for example successfully ...

Estimated Water Requirements for Gold Heap-Leach Operations

Briefly stated, gold heap leaching is a hydrometallurgical process designed to treat amenable low-grade gold ores that contain roughly 0.5 gram per metric ton (g/t) gold to 1.5 g/t gold (Marsden and House, 2006; Wong Wai Leong and Mujumdar, 2010). The ore is stacked by various types of equipment

Leaching - an overview | ScienceDirect Topics

Smithsonian Science Information Exchange, Inc., in Summary of International Energy Research and Development Activities 1974–1976, 2013. 3.0161 USE OF LOW-COST HEAT SOURCES TO IMPROVE THE EFFICIENCY OF HEAP LEACHING OF URANIUM ORES. S. AJURIAGARZA, Atomic Energy Institute, Mexico City 18, Distrito Fed., Mexico

Heap Leaching - Hatch Ltd

Hatch heap leaching capabilities include: optimizing performance through dynamic modeling, leach pad and pond design, ... The resulting data and information is then put into our dynamic heap-leach models to optimize the design and performance of each facility. Blogs.

Heap Leach Solution Management

Heap Leach Solution Management – Decommissioning. The principal objectives of solution management in decommissioning spent heap leach pads are to meet all operative environmental regulations in a cost-effective manner and to leave the pads in a condition where they do not present a long-term liability either to the operator or to the environment.

Heap leaching a stack of gold | MiningFeeds

25-4-2018 · Heap leaching is used to extract gold, copper, silver, uranium, and iodine. This method was first employed to extract copper at the Bluebird mine in the US in the early 1960s, and then by several gold mines in the western parts of the US a few years later. Since then, heap leaching has been adopted successfully by many mines across the world.

Heap Leaching Mining Techniques, Metals Mining, …

Heap leaching is an industrial mining method to dig out precious metals and copper compounds from ore. Process of heap leaching The mined ore is crushed into tiny chunks and heaped on an impermeable stone and/or clay lined leach pad where it may be …

Heap leaching. Computer simulation as an …

1-7-2015 · Heap leaching of precious metals from low-grade ores is highly resource- and energy-intensive process. Lots of heap leaching occupies dozens and sometimes hundreds of hectares of land. In the reverse process at the same time there are hundreds of thousands of cubic meters of toxic sodium cyanide solution.

In situ leach - Wikipedia

In-situ leaching (ISL), also called in-situ recovery (ISR) or solution mining, is a mining process used to recover minerals such as copper and uranium through boreholes drilled into a deposit, in situ.In situ leach works by artificially dissolving minerals occurring naturally in a solid state. For recovery of material occurring naturally in solution, see: Brine mining.

Heap leaching: Could it be an alternative to …

Heap leaching is widely used in modern large-scale mining operations as it produces the desired concentrates at a lower cost compared to conventional processing methods such as flotation ...

What is Heap Leaching? (with picture) - wiseGEEK

6-5-2020 · Heap leaching is an industrial process for extracting precious metals and minerals by dissolving them from ore with liquids known as leaching solutions. Unlike conventional ore refinement processes which utilize extremely high temperatures and highly toxic chemicals, heap leaching offers operators an effective, low cost solution with little, if any, negative environmental impact.