Understanding Sinter and Sinter Plant Operations …

Understanding Sinter and Sinter Plant Operations. satyendra; March 15, 2015; 2 Comments ; fluxes, Iron ore fines, SCFA, sinter, sinter plant. basic sinter, sintering machine,; Understanding Sinter and Sinter Plant Operations Sintering is a process of agglomeration of fine mineral particles into a porous and lumpy mass by incipient fusion caused by heat produced by combustion of solid fuel ...

Sinter plant - Wikipedia

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the stone properties of the ingredients. The purpose of sinter are to be used converting iron into steel.

Sinter Plant - an overview | ScienceDirect Topics

03.02.2012 · After acceptance of the revised Detailed Project Report, in February 1981, a contract was signed with USSR for preparation of working drawings for coke ovens, blast furnace and sinter plant. The blast furnace foundation was laid with 1st mass concreting in the project in January 1982. The construction of township also started. But SAIL, the original holding company of VSP was finding it …

sinter plant process flow diagram - BINQ Mining

flow diagram of sinter plant. Sinter plant The largest sinter plant is located in Chennai, India, and employs 10,000 people. Process. Preparation of the ores. Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux (lime stone) fines. Online Chat

03 Sinter plant - durag group

SINTER PLANT PRODUCTS FOR SINTER PLANTS. Here you can see a schematic representation of a sinter plant equipped with DURAG GROUP devices. Please click on a sub-region to get more details about Products Combustion or Products Environment.

The Sintering Process of Iron Ore Fines – IspatGuru

The process of sintering begins with the preparation of the raw materials consisting of iron ore fines, fluxes, in-plant metallurgical waste materials, fuel and return fines of the sinter plant. These materials are mixed in a rotating pelletizing drum and water is added in order to reach proper agglomeration of the raw materials mix. This agglomeration is in the form of micro-pellets. These ...

flow process sinter plant - ecocenture.be

sinter plant process flow diagram - BINQ Mining Apr 25, 2013 sinter plant process flow diagram Posted at , Process flow chart , The 267,300 TPA Sinter Plant has been set up for the production of sinter to be , Get More Info. SINTER PLANT AND BASIC OXYGEN FURNACE WASTE HEAT , SINTER PLANT AND BASIC OXYGEN FURNACE WASTE HEAT , A schematic process flow diagram of …

030301 Sinter plants - European Commission

CH no sinter plant D 0.08 0.11 0.62 0.88 0.89 refers to hot crushing and sieving D 6.00 0.80 14.10 5.90 1.30 27.70 stack emission from sintering process; maximum concentration observed at one DK no sinter plant E 6.00 acc. to information obtained from TNO F 18.00 10.00 100.00 EFs estimated from German results GR no sinter plant I no data obtained

flow process sinter plant - …

Sinter plant process flow diagram in jsw Sinter plant process flow diagram in jsw Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, Sinter plant process flow diagram in jsw, quarry, aggregate, and different kinds of minerals. 【Service Online】 sinter plant process ...

CHAPTER-11 FUNDAMENTALS OF IRON ORE SINTERING

The process of sinter making originated from a need to make use of fines generated in mines and in ore benefiCiation plants. With the development of sintering technology, a sintering plant has become a tremendous success for providing a phenomenal increase in productivity and saving in coke rate to the blast furnace. The technology of sinter making has undergone radical changes both in ...

flow process sinter plant - denarrenkoning.be

flow process sinter plant,flow sheet about how to process copper Introduction Process in buying copper ore flow chart faq about stone crusher price gold ore refining... Sinter Plant Process. The sintering process of iron ore fines sintering plants are normally associated with the production of hot metal in blast furnaces in integrated steel pants... CHINA STEEL | The Flow Sheet of Sinter Plant ...

Blast Furnace Operation - an overview | …

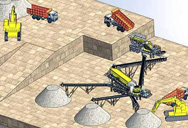

Schematic diagram showing the material flow in a sinter plant (Anon 1, 2014). The sintering process begins with the preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and return fines from the sinter plant and blast furnace as well as recycled ferruginous materials from downstream iron and steelmaking processes ...

Iron Ore Processing Sinter Plant In Short

Iron Ore Processing Plant Plan. Iron Ore Processing Plant. Iron is found in the worlds oldest and most widely used, is the largest amount metal, the metal consumption of about 95 of total consumption.Iron ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon content.The so-called iron ore deposits is the main target of.

Sintering | Eurotherm by Schneider Electric

Materials enter the sinter plant from storage bins. They are mixed in the correct proportions using weigh hoppers, one per storage bin, except for the return fines for which an impact meter is used instead. Weighing is continuous, as is the whole sintering process. The weighed materials pass along a conveyor to the mixing drum where water is added either manually or as a calculated percentage ...

How does a sinter plant work? - Quora

In any Sintering process lump or fine particles are compacted or fused together, to form a bigger mass without actually melting the particles. In this answer I will stick to the sintering process of Iron and Steel Plants. Iron ore fines are agglo...

THE PERFECT SINTER PLANT SOLUTIONS FOR FULLY OPTIMIZED ...

to bring your sinter plant in line with the latest technologies. Our lifecycle management spans the entire service life of the sinter plant, offering much more than just after-sales service. • Extensive experience in the sintering process – building and modernizing sinter plants for over 5 decades • Efficient project …

(PDF) Iron Ore Sintering: Process

charged onto the sinter machine. A commercial plant using. HPS process with an annual capacity of 6 million tons per . annum was built by the JFE Steel Corporation at Fukuyama (Lu and Ishiyama ...

Latest Generation Sinter Process Optimization Systems

Latest Generation Sinter Process Optimization Systems Thomas Kronberger, Martin Schaler and Christoph Schönegger Siemens VAI Metals Technologies GmbH (Siemens VAI) Linz, Austria 1. Introduction SIMETAL Sinter VAiron is an advanced process optimization system which covers the sinter production process from ore preparation in the blending yards and sinter plant up to the blast …

Flow chart of sinter plant of iron ore fines ...

Flow diagram of sinter plant electroradarco. The largest sinter plant is located in Chennai, India, and employs 10,000 people Process Preparation of the ores Main feed into a sinter plant is base mix, which consists of iron ore fines, coke fines and flux lime stone fines In addition to base mix, coke fines, flux fines, sinter fines, iron dust collected from plant dedusting system