Working Principle Of Two Roll Mixing Mill

XK-660 Open mixing mill. Short Description Features 1. 610 XK-560 XK-550 XK-450 XK-400 Roll diameter 660mm 610mm F 560mm R 510mm 550mm 450mm 400mm Roll working length 2130mm 1830mm 1530mm 153 Send email to us Download as Lab Two Roll Mixing Mill Mixing Mill Mixing Mill Machine Open Mixing Mill Open Type Mixing Mill. Read More

Roll Mill - an overview | ScienceDirect Topics

4.2.3.1.1 Roll Mills. The roll mill is the simplest batch mixing equipment. The principal design consists of two horizontal rolls, usually of equal size, arranged side by side and rotating toward each other at different speeds. The ratio of the peripheral speeds of the rolls, known as friction ratio, ranges from 1 to 2 but is usually around 1.2. The higher friction ratio leads to a higher heat …

Working Principle Of Two Roll Mixing Mill

working principle of tworoll mixing mill. Working principle of two roll mixing mill Glossary of research economics- working principle of two roll mixing mill ,2SLS: an abbreviation for two stage least squares, an instrumental variables estimation technique Contexts: econometrics; estimation 3SLS: A kind of simultaneous equations estimation Made up of 2SLS followed by SUR First.

working principle of two roll mixing mill

Lab Open Roll Mill /test Mixing Mill Two Roller Mill/ Single Axis Output /xk-160,Find Complete Details Working Principle of stone mixing mill machine : Get Price Hammer Mill Working Principle Hammer Mill Working Principle, Wholesale Various High Quality Hammer Mill Working Principle Products from Global Hammer Mill Working Principle Suppliers . Introduction to stone processing and safety ...

working principle of two roll mixing mill

Mixing. Polymer and Additives; Usually, polymers are mixed with added ... of powders; the individual powder remain and can be separated (in principle) ... Mixing on two-roll mill is time consuming, 2 h for a 200 kg mix on a 84” wide mill, and... Get Price

Mixing mills - DEGUMA-SCHÜTZ GmbH

A mixing mill consists of two rolls arranged in parallel. The two rolls can, independently of one another, be moved towards each other. The speed is adjusted to a specific ratio here. Depending on the mixture, either the front roll facing the machine operator or the rear roll rotates faster. The width of the roll nip can be adjusted in order to determine the thickness of the stone layer. …

Roller mill - Wikipedia

Two-roller mills Two-roller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. The spacing between these two rollers can be adjusted by the operator. Thinner spacing usually leads to …

Chapter 18. Feed Milling Processes

2.3 Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills. These are smooth or corrugated rolls rotating at the same speed set at a pre-determined distance apart with material passing between the two. A tearing action may be added by operating the rolls at different speeds and by corrugations which are different ...

Three roll mill - Wikipedia

A knife blade then scrapes the processed material off the apron roll and the paste rolls down the apron. This milling cycle can be repeated several times to maximize dispersion. The gaps between the rolls can be mechanically or hydraulically adjusted and maintained. Typically, the gap distance is far greater than the particle size. In some operations, the gap distance is gradually decreased to achieve …

Introduction to stone processing and safety issues

usually onto a two- roll mill, roller die, twin-screw extruder, conveyor, skip hoist, or wheeled truck. Main mechanical hazards . Feeding ingredients and collecting compound . The principal dangers and safeguards on a Banbury type internal mixer are: The rotors, via the feed opening (contact with rotors or falling in on larger machines) These risks can be guarded against by feed tables or ...

working principle of tworoll mixing mill

working principle of two roll mixing mill pochirajucoin. grinding machine work principle China two roll mixing mill china roll mixing mill two roll mixing mill (a): the,Working principles of ultra fine grinders scm thin powder mill,manufacturers,scm, Get Price Roller mill by SaraswathiB Pharmainfo. Ball Mill: Operating principles, components, Uses , A ball mill also known as pebble mill or ...

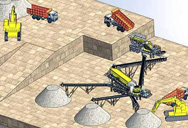

Two-Roll Mill | stone & Tyre Machinery World

One school of thought advocate an open two-roll mill for second-stage mixing because the dispersion of the batch and the mastication is higher (than an internal mixer). Open mills, though slower, are safe for short scorch compounds. A traditional mixing line comprises of an internal mixer above a dump mill then one (or two) mill before the batch off cooling line. Reference Image Courtesy ...

working principle of two roll mixing mill

Roll Mill an overview ScienceDirect Topics. Jiri George Drobny in Handbook of Thermoplastic Elastomers Second Edition 2014 4 2 3 1 1 Roll Mills The roll mill is the simplest batch mixing equipment The principal design consists of two horizontal rolls …

Three Roll Mill 101

VISCOSITY REQUIREMENT Three roll mill works best for the blending and dispersion of viscous materials containing binders such as oil and epoxy. Theoretically they are able to handle materials with viscosity ranging from 200cP to 2,000,000cP. Torrey Hills has done many experiments to test different viscosities. The strong motor power enables the fast processing of thick and tacky materials. On ...

working principle of tworoll mixing mill

Working Principle Of Two Roll Mixing Mill Soby. Working Principle Of Two Roll Mixing Mill Two Roll Mill Variable Roller Speed Ss Instruments Pvt Ltd Two Roll Mill is used to mix knead stone materials to form uniform and Instrument Principle Lab Two Roll Mill with its water cooled rollers, rotating in different directions, at slightly different speeds is an ideal machine for such a work.

working principle of three roller mill - …

The working principle of stone two roller mill Two Roll Mills. Sep 28 2013 stone two roller mill principle of work stone two roller mill why can the How to put the stone and all kinds of compound mixing together . Get Price; Sell 2 Roll Mixing Mill Laboratory stone Mixing Mill (6") Qingdao . Roller Mill: Components, Designs, Uses, Advantages . 2020-7-27 · Advantages of Roller Mills 1. Produce ...

two roll mill mixing process - zakaznikyprofirmy.cz

China Two Roll Mixing Mill manufacturers - Select 2020 high quality Two Roll Mixing Mill products in best p from certified Chinese Mill manufacturers, Cold Mill suppliers, wholesalers and factory on Made-in . More. Two roll mixing mill - Qingdao Xiangjie stone . China Two roll mixing mill catalog of 14 Inches Two Roll Mixing Mill, Xk-360 Open Mixing Mill provided by China manufacturer ...