India Iron Ore Mining Process Equipment - ie13.fr

Introduction iron ore mining process flow including iron ore crushing, magnetic separation, grinding, classification and flotation, and iron ore mining equipments as ... Contact Supplier Iron Ore Beneficiation Process Machine In India - XSM

Iron ore washing plant India - YouTube

05.05.2015 · Iron ore washing is the process to reduce contaminants and thereby increasing the iron content of the raw iron ore, known as increasing the Fe value. Our tec...

Iron-process iron ore mining in india - YouTube

30.09.2012 · If the iron that the ore produced was cold short, one would search for a new source of iron ore. The second method involves oxidizing the phosphorus during the fining process by adding iron oxide ...

Iron Ore Mining Service in India

Daitari Iron Ore Mines- for mining, processing and transportation of ore through 22 Km road to stockyard and railway siding. The period of this project is 10 years with a target of 21.50 Million MT and mobilization is under progress.

Iron Ore News - Iron Ore Mining, Investment, …

Iron Ore mining, investment and price news from MINING.com. The latest news on iron ore mines and properties, mining companies and iron ore prices.

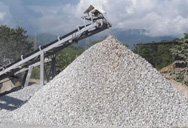

Iron Ore Processing for the Blast Furnace

Creating steel from low-grade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing, and shipping. The process of mining low -grade iron ore, or taconite, requires massive resources. Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required. The equipment used includes diamond -bit rotary drills, hydraulic ...

Iron Ore Mining Process Flow Chart,Iron Ore …

Iron Ore Mining Process primarily for the production of powdered Iron Ore. Iron can be used to produce small metal parts, to avoid large pieces of iron waste; iron can be used for stone experiments, which is chunks of iron impossible. So Iron Ore Mining Process is a very significant technological breakthrough.

Mining separation and sorting equipment for …

Since our founding, STEINERT has been a pioneer in mechanical mining separation and processing, e.g. ore sorting equipment. As a leading global manufacturer of advanced sorting and magnet-based systems, we are continually developing new high-tech solutions to meet the challenges of our customers: when it is necessary to protect equipment from tramp iron in material recovery facilities or to ...

Mining in India - Wikipedia

Indian mining industry provides stone opportunities to around 700,000 individuals. As of 2012, India is the largest producer of sheet mica, 2015 the fourth largest producer of iron ore, alumina, chromite, and bauxite in the world. A coal and iron ore project is in the fifth largest reserve in world. Indias metal and mining industry was estimated ...

Mining companies in India: Profiling nine of the …

18.02.2019 · Major mining companies in India National Mineral Development Corporation. Incorporated in 1958, National Mineral Development Corporation (NMDC) is owned by the Government of India and controlled by the Ministry of Steel. The company is involved in the exploration of various minerals such as iron ore, copper, rock phosphate, limestone, gypsum ...

Iron ore pelletizing systems - liming

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don’t need beneficiated, fines which are generated can be pelletized and used instead of being disposed of.

Mining of Iron Ores – IspatGuru

The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body. This leads to a mathematical ...

Iron Ore - Leaders in Mineral Processing Worldwide

With teams located in major mining regions worldwide, we can work with you to supply Iron Ore beneficiation solutions across all stages of the project lifecycle. To find out more about how we can drive down operational costs and extract maximum value from your mineral processing operations across the project lifecycle contact our local team today .

Iron Ore Mines In India Suppliers, all Quality Iron …

Iron ore mining equipment SF1.2 flotation cell machine price in India 10 Ton Per Hour Iron Ore Processing Plant Overflow Grinding Ball Mill For Sale In India Best Price DP440 Single-Cylinder Hydraulic Cone Crusher For 200tph Iron Ore Crushing Line In India

Iron ore mining process and iron ore mining …

Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse. Common iron ore crushers are jaw crusher, cone crusher and fine jaw crusher.

Iron Ore Mining Services In India

Iron Ore Mining Services In India Alligator hammeron conveyor belt lacing provides a strong grip and uniform tension across the width of the belt. the lacing has a low profile that minimizes noise as it moves over the conveyor rollers, reduces the risk of the lacing interfering with the belt or conveyor...

Gold Mining Equipment - Metallurgist & Mineral …

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment.Our equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE’ offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, …

Iron Ore Processing Plants - Iron Ore Wash Plants …

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process.