GMD system for Toromocho mine | ABB

1 x 28 MW GMD to power the 40 ft SAG mill; 2 x 22 MW GMDs to power two 28 ft ball mills ; The sites altitude and high power system required ingenuity and flexibility when in came to engineering the three systems. Some of the changes compared to GMDs for lower altitudes were: N ew cooling system able to dissipate heat generated by the most powerful GMD at this altitude

SAG mills (semi-autogenous grinding mills) - liming

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing liming to produce the worlds largest SAG mill of 42’ in diameter drawing power at 28 MW. Today, liming is the world leading supplier of gearless SAG mills operating globally.

Gearless mill drives - Grinding | ABB

ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, service-friendly and fit for purpose design to provide highest throughput, reliability …

SAG Mill - Official Feed The Beast Wiki

17.06.2020 · "Power Use: 80%" means a recipe will only require 80% of its default energy cost to be processed. However, the SAG Mill always works at a set energy usage rate; if a recipe requires less energy, the stone will be completed faster. Therefore, 80% Power Use equals 25% faster processing speed. Bonus Output modifies chance-based outputs. The given percentage is applied to the base …

sag mill gmd how does it work - BINQ Mining

CONGA: THE WORLD’S FIRST 42 FOOT DIAMETER 28 MW GEARLESS SAG MILL. The test and study work showed that a single line 42 ft SAG mill circuit gave the most … The 42 ft diameter Conga SAG mill GMD power density value of 0.67 is not an … »More detailed

Mill power draw models - SAGMILLING.COM

Mill Power Draw Models. The mill power draw models are used to predict how much power will be consumed by a particular type of mill, mill geometry and set of mill operating conditions. This power is transferred to the ore and used to predict the throughput when combined with the specific energy consumption models. Models of this type do not predict the particle size distribution of a milled ...

CONGA: THE WORLD’S FIRST 42 FOOT DIAMETER 28 MW …

equivalently powered 42 ft SAG mill, Newmont made the decision in 2010 to purchase a 42 ft SAG mill from liming and a 28 MW GMD from ABB. THE MILL Needless to say “reliability” is a key word at every stage of the project. Although mill structure failures have not occurred in large GMD SAG mills, the mill design was not exempt from a reliability

Difference Between Sag Mill vs Ball Mill - …

SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially. Interior of the drum uses the lifting plates. These plates inside the drum are …

Mill (grinding) - Wikipedia

A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. The largest SAG mill is 42 (12.8m) in diameter, powered by a 28 MW (38,000 HP) motor. A SAG mill with a 44 (13.4m) diameter and a power of 35 MW (47,000 HP) has been designed.

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL …

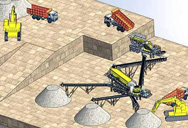

SAG mills have a power higher than 10 MW. Even ball mills have a power larger than 10 MW. For this reason, they have an important impact in energy consumption and in the operation of the power distribution system. Figure 1. Picture of a typical GMD system for a SAG mill Figure 2 presents the power circuit of a cycloconverter fed synchronous ...

Grinding Mill Gear Assembly

We will begin with the mill’s bull gear assembly and work towards the motor, The BULL GEAR, sometimes called the RING GEAR is designed to turn the mill transforming the energy of the motor into motion for the mill. By mill we refer to Ball Mills, Rod Mills and SAG Mills. Anything gear and pinion really. The discharge end of the mill; For the operator this only becomes a problem should the ...

A Mill Power Equation For Sag Mills

Sag mill capcity le in40dagenonline.Nl.Sag mill capcity le.Autogenous and semiautogenous mills.Gearless mill drive gmd technology has further expanded the use of large agsag milling allowing to produce the worlds largest sag mill of 42 in diameter drawing power at 28 mw.Today, is the world leading supplier of gearless agsag mills.

Autogenous and Semi-Autogenous Mills | FLSmidth

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. Fuller-Traylor SAG/AG Mills range in size from 4.3m through 12.2m in diameter with powers as high as 28,000 kW.

2009 Gearless Mill Drives

Peñasquito México SAG-Mill 38 18,300 Scheduled 2010 Peñasquito México SAG-Mill 38 18,300 Scheduled 2009 Plant Country Type of Mill ID of Mill (ft) Rated Power (kW) Start-up

Grinding mills - for mining and minerals …

Every mining operation has a unique grinding process. liming has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as start-up, operation, and optimization of your mill.

Autogenous and Semi-Autogenous Mills - …

01.01.2016 · AG/SAG Mill Power. In designing crushing–grinding flow sheets, correct estimations of mill power draw are important as it serves as one of the deciding factors for selecting an option between AG/SAG mills. In most cases, the circuit with the least or optimal power consumption is the preferred choice. The mill power is usually determined in a laboratory scale mill and if possible, followed by ...

SIMINE Gearless mill drives

The TRANSVEKTOR control system used on high-power mill drives has gone through a long development phase. A lot of experience has been gained with this system during the last 33 years. The first gearless drive with this control has been operating successfully for more than 30 years. A phase of continuous improvement and further develop-ment followed its launch. Today, the TRANSVEKTOR …

SAG Mill Control: It Shouldnt be that Hard

Semiautogenous grinding (SAG) mills up to 44-ft diameter with 35-MW gearless mill drives (GMDs) are available. In January, for example, a 1,210-ton AG mill—considered to be the largest ever built—was shipped from the CITIC Heavy Machinery plant in China to the Sino Iron project in Australia.